"We strive to continuously improve our sustainability performance."

Sustainability is a fundamental part of our business. From the products and services we offer to the way we operate, we are committed to making a positive impact on the environment and the communities in which we work. We understand that sustainability is about more than just being "green" – it's about continually improving our performance and finding innovative ways to reduce our environmental impact.

That's why we constantly look for ways to reduce our carbon footprint, conserve resources, and minimize waste. Whether it's through energy-efficient manufacturing processes, sustainable sourcing, or employee engagement programs, we are dedicated to building a more sustainable future for all.

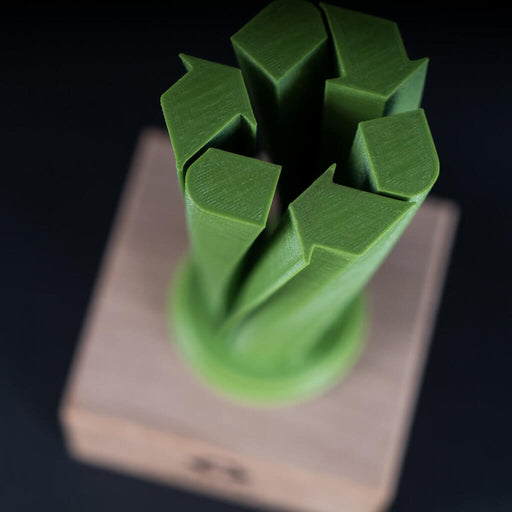

Is 3D Printing Sustainable?

3D printing, also known as additive manufacturing, can have both environmental benefits and drawbacks depending on the specific technology and materials used. On the one hand, 3D printing has the potential to reduce waste and energy use compared to traditional manufacturing processes, which often involve cutting, shaping, and assembling materials. 3D printing also allows for creating customized and complex products using fewer materials, which can further reduce waste.

However, 3D printing also has some environmental drawbacks to consider. Many 3D printing technologies rely on plastics and other synthetic materials, which can hurt the environment when they are produced and disposed of. In addition, 3D printing may require energy-intensive processes and specialized equipment, which can contribute to carbon emissions.

Overall, the sustainability of 3D printing depends on various factors, including the materials and processes used, the scale of production, and the end-of-life disposal of printed products. To maximize the environmental benefits of 3D printing, it is essential to consider these factors carefully and to adopt best practices in the design and production of 3D printed products.

Sustainable materials

Recycled Plexiglass

One of the materials we use is recycled plexiglass, a recycled version of the popular thermoplastic acrylic polymer known as polymethyl methacrylate (PMMA). Using recycled plexiglass reduces our reliance on virgin materials and diverts plastic waste from landfills.

In addition to its environmental benefits, recycled plexiglass has several practical advantages. It is a strong, durable, and transparent material well-suited to various applications, including producing awards, signs, displays, and other products that require a clear, high-quality finish. We are proud to use recycled plexiglass in our production processes.

Compostable Trophies

At Fabit, we are used to creating awards that last forever. However, with our compostable materials, we can offer the opportunity to give an award to mother earth. This unique material will degrade within 6-8 months.

Compostable awards are available in the following colors: White, Desert, Brown and Black.

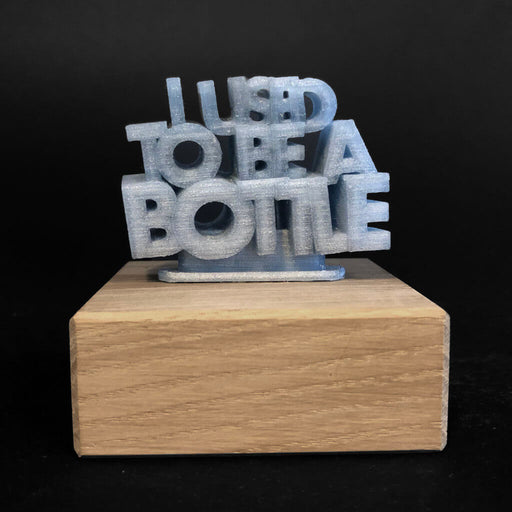

Recycled PET

Our PET awards are 100% recycled from beverage containers, water bottles and fabrics. The surface is rough, giving the award an authentic eco-look. For the bases we use FSC approved wooden blocks.

Recycled PET awards are available in the following colors: Clear, White, Leaf Green, Dark Blue, Red and Black.

FSC Certified Wood

FSC-certified wood comes from forests that are managed in an environmentally responsible, socially beneficial, and economically viable way. Using FSC-certified wood ensures that the wood we use is sourced from well-managed forests that are protected from illegal logging, habitat destruction, and other unsustainable practices. We are proud to use FSC-certified wood in 100% of our wood-containing trophies.

In addition to its environmental benefits, FSC-certified wood is also a strong, durable, and visually appealing material that is well-suited to various applications, such as the production of awards, trophies, decorative items, and other products that require a natural, high-quality finish.

Sustainable Packaging

Recycled Cartons

At Fabit, we are committed to using sustainable materials in all operations, including in our packaging. We use recycled cartons for many of our packaging needs. In addition to its environmental benefits, the recycled carton is a strong and durable material that is well-suited to protect our products during shipping. We are proud to use recycled cartons in our packaging and are always looking for ways to incorporate sustainable materials into our operations.

Bio-degradable peanuts

Bio-degradable peanuts are a type of packing material that we use, which is made from biodegradable materials, such as plant-based polymers or starch. They are often used as a replacement for traditional packing peanuts, made from non-biodegradable plastic, and can take hundreds of years to break down in landfills. Bio-degradable peanuts are designed to break down faster and can be composted with other organic materials.

Benefits of bio-degradable peanuts in packaging include:

- Bio-degradable peanuts break down more quickly and do not contribute to plastic waste in landfills.

- Bio-degradable peanuts can be easily disposed of along with other organic materials, such as food waste, making them a more convenient option.

- They can be customized to meet the specific needs of different products and packaging requirements.

Overall, using bio-degradable peanuts in packaging can help reduce the environmental impact of packaging materials and provide a more sustainable and convenient option.